Industries We Serve

Steel & Metallurgy

Cement & Lime Kilns

Non-Ferrous Industries

Petrochemical & Incineration

A Tradition of Strength, A Vision for the Future

Founded on a legacy that began in 2000, Sri Radhansh and Company is built on decades of expertise in refractory raw material processing. Today, we operate as a unified manufacturing organization with three state-of-the-art units focused on calcination, grinding, and shaping — delivering quality that meets the demands of modern industry.

With our robust infrastructure, we are one of the only players in the region offering end-to-end refractory solutions — from raw material calcination to finished custom-engineered shapes.

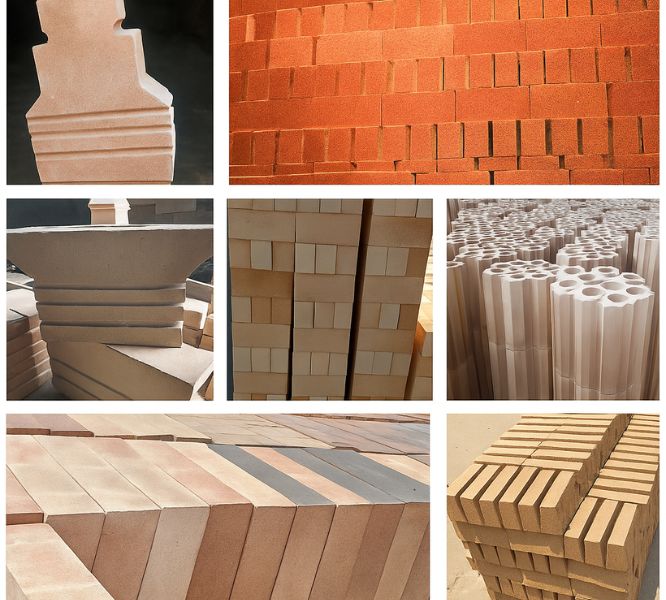

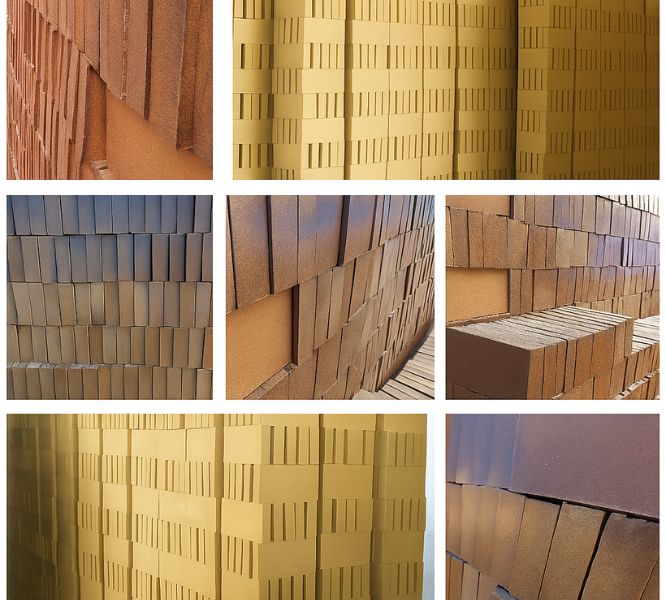

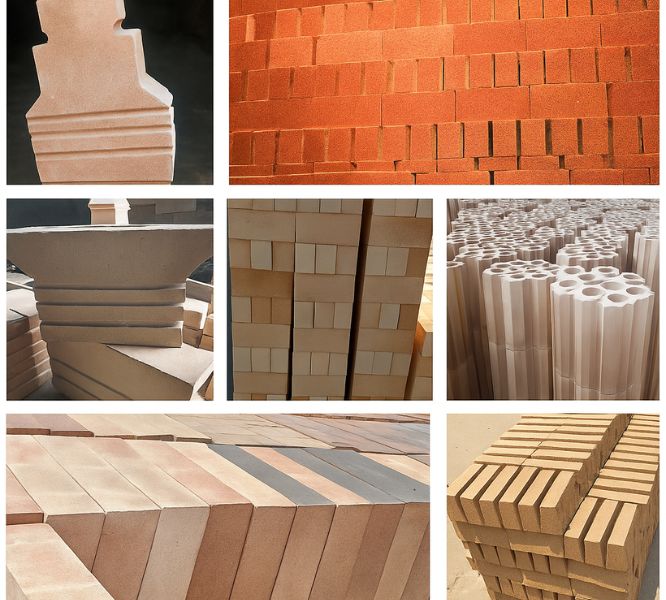

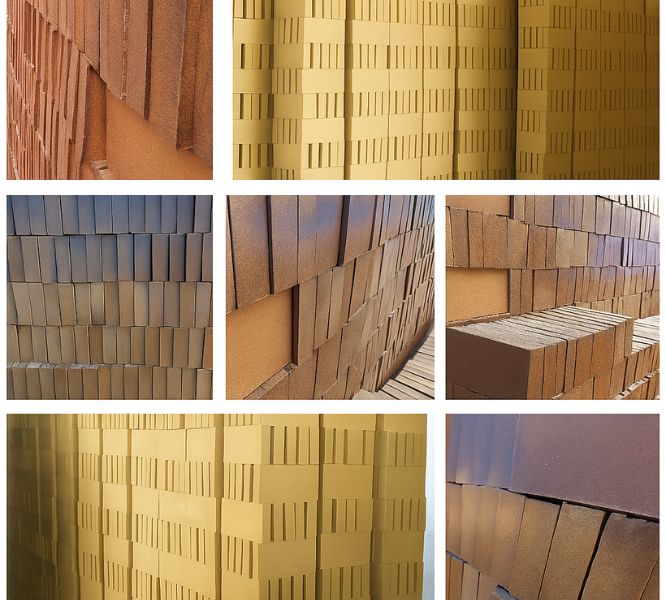

At Sri Radhansh and Company, we offer a focused yet evolving portfolio of refractory products — each designed to meet the exacting demands of high-temperature industrial environments. Our product range combines material science, engineering know-how, and a vertically integrated manufacturing process to ensure optimal performance, consistency, and quality.

Used in refractories, abrasives, and anti-skid road materials. Our calcined bauxite is processed in-house, ensuring stable chemical composition and consistent sizing.

These are dense, high-strength bricks designed for severe service conditions, thermal shock resistance, and high mechanical load.

Manufactured using selected raw materials with high silica and low iron content. Ideal for corrosive environments.

We are actively expanding into:

Used in refractories, abrasives, and anti-skid road materials. Our calcined bauxite is processed in-house, ensuring stable chemical composition and consistent sizing.

These are dense, high-strength bricks designed for severe service conditions, thermal shock resistance, and high mechanical load.

Manufactured using selected raw materials with high silica and low iron content. Ideal for corrosive environments.

We are actively expanding into:

Whether you’re looking for reliable supply, custom engineering, or a new manufacturing partner — we’re here to deliver

WhatsApp us