Engineered for Performance, Built for Reliability

At Sri Radhansh and Company, we offer a focused yet evolving portfolio of refractory products — each designed to meet the exacting demands of high-temperature industrial environments.

Calcined Bauxite

Alumina Content: 68% to 82%

Used in refractories, abrasives, and anti-skid road materials. Our calcined bauxite is processed in-house, ensuring stable chemical composition and consistent sizing.

Applications:

• Refractory castables and bricks

• Anti-skid surfaces for roads/runways

• Abrasives and precision components

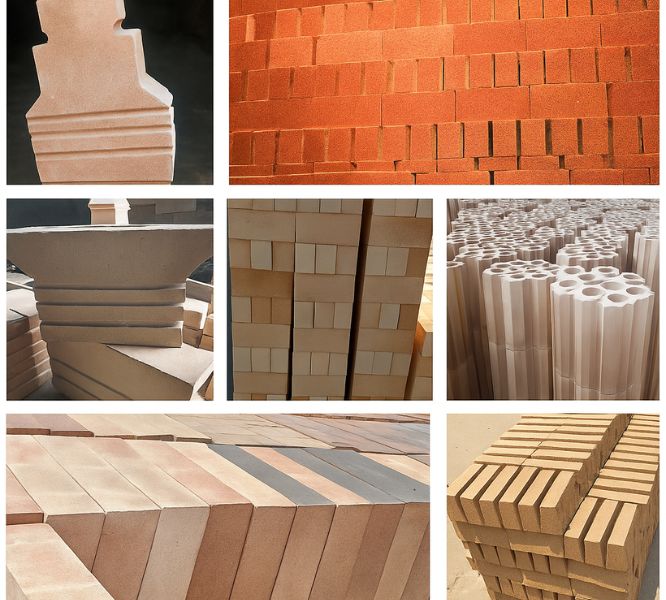

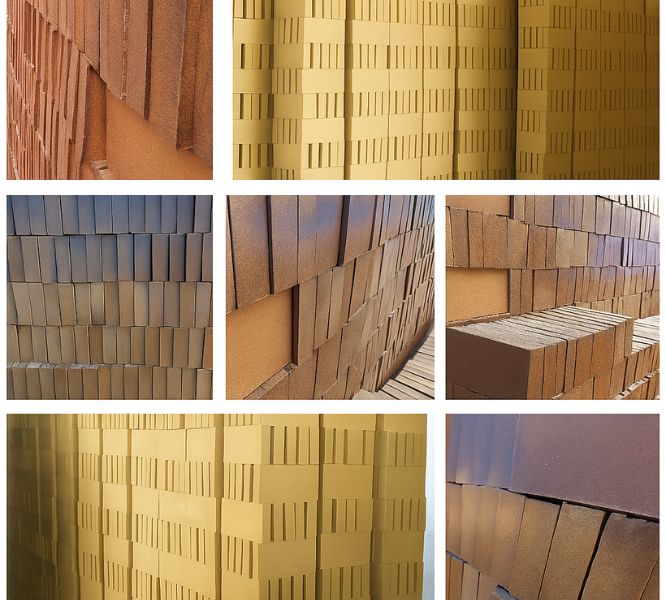

High Alumina Bricks and Shapes

Alumina Content: upto 80%

These are dense, high-strength bricks designed for severe service conditions, thermal shock resistance, and high mechanical load.

Applications:

• Cement kilns

• Boilers & Incineration Chambers

• Backup linings in steel and non-ferrous

furnaces

• Steel ladles and tundishes

• Blast furnaces and hot metal mixers

• Rotary kilns and calcination chambers

• Glass Tank Furnaces

Acid-Resistant Bricks & Shapes

Specialty: Resistant to chemical and acid attack

Manufactured using selected raw materials with high silica and low iron content. Ideal for corrosive environments.

Applications:

• Chemical plants and reaction towers

• Pickling tanks

• Chimneys and effluent treatment systems

Upcoming Products

We are actively expanding into:

• High-Grade Refractory Raw Materials (in various custom specifications)

• New Grades of Shaped Products