1. Our Commitment to Quality

At Sri Radhansh and Company, quality is embedded in our process — not inspected at the end. From raw material selection to final inspection, our rigorous quality systems ensure that every product meets industry standards and client expectations. We follow structured quality control procedures for every batch and maintain strict traceability of raw materials, processing, and finished goods.

2. In-House Laboratory & R&D Center

Our on-site laboratory is fully equipped for both routine quality control and ongoing research and development. Whether it’s improving existing grades or developing entirely new compositions, we back our products with solid lab data and technical know-how.

3. Lab Capabilities

Our Laboratory

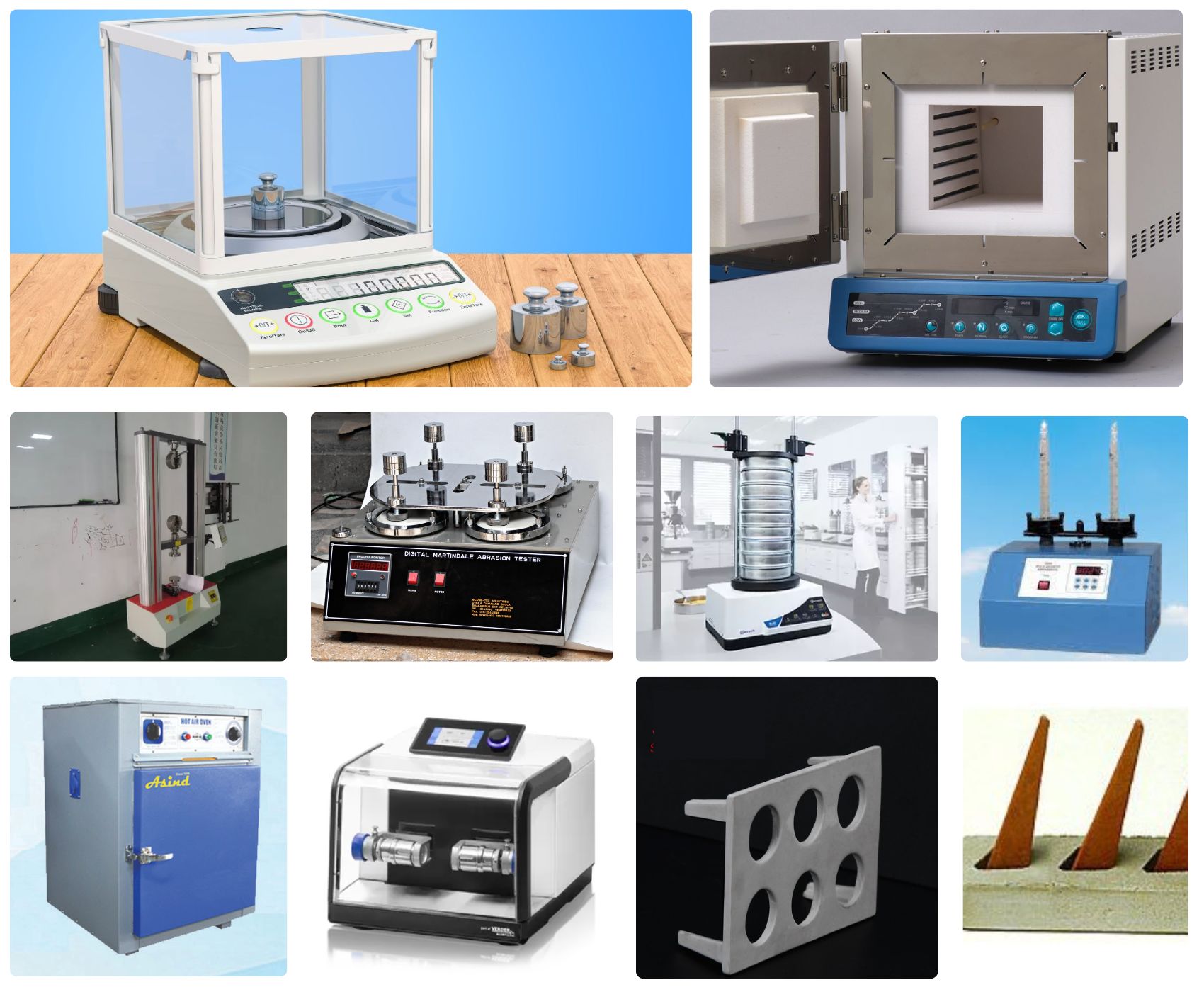

Our laboratory is equipped with instruments and tools to perform comprehensive analysis and testing of refractory raw materials, intermediate powders, and finished shapes.Major Testing Equipment

- Digital Weighing Balances (High Precision)

- Muffle Furnace (up to 1600°C)

- Universal Strength Testing Machine (Cold Crushing Strength / MOR)

- Abrasion Resistance Tester

- Bulk Density Measurement Apparatus

- Pyrometric Cone Equivalent (PCE) Testing Set

- Slag Resistance Test Setup

- Sieve Shaker with Full Sieve Set (for granulometry)

- Hot Air Oven (for moisture content analysis)

- Laboratory Mixers and Sample Presses

- Sample Drying Trays, Crucibles, Refractory Holders

Analytical Capabilities

- Capable of analyzing full chemical composition of refractory raw materials and shapes

- Alumina (Al₂O₃), Silica (SiO₂), Iron Oxide (Fe₂O₃), Titania (TiO₂), Alkalis, and Trace Elements

- Test support for all products manufactured in-house

4. Focus on R&D

Our R&D initiatives support product diversification and process optimization. From developing high-performance shapes to optimizing firing curves and raw mix design, we aim to remain one step ahead in refractory innovation.

Our lab works closely with our production team to:

• Improve material performance

• Reduce energy consumption in firing

• Test alternative raw materials

• Develop new compositions tailored to client needs

5. Reliability Backed by Data

Every dispatch is backed by data. Our test reports help clients meet their own internal quality audits and third-party inspection norms — ensuring long-term partnerships built on trust.